Plywood

I S O 9 0 0 2 Q U A L

I T Y

M A N A G E M E N T S Y S T E M

Product description

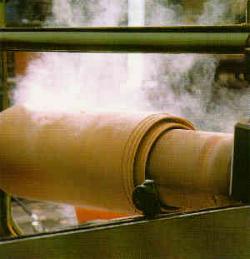

The input material for sheet plywood

is peeled veneer with the thickness of 1.7 mm +/- 0.15 mm.

The layers of veneer are glued together

with phenol-formaldehyde glue, with alternate directions of the fiber.

Based on the client's request we deliver plywood with glue enriched with

substances preventing moisture, relieved plywood with combined beech/birch

veneers as well as cushion plywood with rubber center.

Produdct-line

Surface-finished plywood with phenolic

foils with smooth and antislip surfacePlywood for general usePlywood for

construction purposes

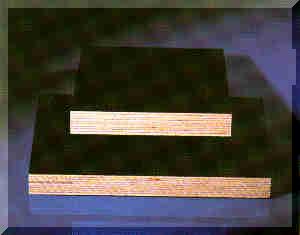

1. PLYWOOD SURFACE - FINISHED WITH

PHENOLIC FOILS WITH SMOOTH AND ANTISLlP SURFACE

Wood Beech (beech/birch,beech/rubber)

Phenolit foil

The Finish foil DYNORESIN with the

weight of 167 g/m2 prevents the penetration of moisture through the board's

surface.

Surfoce Smooth

Raster (grid) - antislip plywood

Dimensions

Width x Length: 1 250 x 2 500 and 1

500 x 2 500 mm

Thickness: 8,11, 15, 18, 21, 24, 27,

30 mm

Number of layers: 5, 7,10,12, 13,15,17,

19

Physical end mechanical characteristics

Density: max. 800 kg/m3

Longitudinal bending strength 490175:

min. 60 MPa

Transverse bending strength according

to the STN 490175 standard: min.30 MPa

Longitudinal shearing strength at boiling

point EW 100, the STN 490175 standard: min.1,0 MPa

Humidity at the time of shipment: max.10%

Combustibility according to the STN

730823 standard: C2 level

The gluing quality according to the

STN 490173 standard is in compliance with the AW100 standard for direct

permanent exposure to weather conditions. The characteristics of the product

comply with the E 1 emission class.

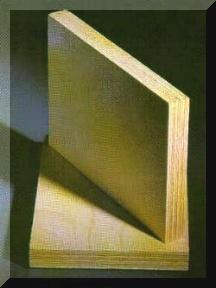

2. PLYWOOD FOR GENERAL USE

Wood Beech (beech/birch,beech/rubber)

Ouality

Determined according to the facial

and reverse side.

According to the number of defects

on the face surface the boards are classified into five grades.

side/quality 1.

2. 3. 4. 5.

foce/bock B/B B/BB BB/BB BB/C C/C

Dimensions Width x Length:

1 250 x 2500 and 1 500 x 2 500 mm

Thickness: 8,11,15,18,21,27,30 mm

Number of layers: 5, 7,10,12,13,15,17,19

Physical end mechanical

Corresponding with other kinds of plywood

characteristics.

3. MULTIPLEX

Wood Beech

Quality

Determined according to the facial

and reverse side. According to used veneer on the surface, the boards are

classified into grades.

Ouality 1.

2. 3.

Foce/Bock A/B B/BB BB/BB

Quality A/B means sliced facing veneer.

Dimensions

Width x Length: 2500 x 1250; 2500 x

1500

Physical and mechanical Corresponding

with other kinds of plywood characteristics

4. PLYWOOD FOR CONSTRUCTION

Wood Beech

Surfoce With the glue applied on both

sides, this plywood is manufactured in quality grade only. Some defects

are tolerated as long as they do not impare the mechanical characteristics

of the board and its usage.

Dimensions Width x Length: 1

250 x 2 500 mm

Thickness: 8,11,15,18,21,24,27, and

30 mm

Number of layers: 10,12,13,15,17,19

Physical and mechanical

Corresponding with other kinds

of plywood characteristics.

General conditions for sstoring

plywood

Plywood must be stored horizontally

on support plates of the same thickness without permanent contact with

the soil. The distance between the support plates must allow for no bending

of the boards. In case of long storage outdoors it is necessary to cover

the boards and protect them against weather conditions. The name of watertight

plywood indicates that the boards are glued with watertight glue. The glued

joint must remain strong even afer the boiling test while still maintaining

its natural wood characteristics.

Information for the user

For processing, we recommend using

of circular saws with hard-metal tips. The newly cut edges must be protected

with protective coating. Plywood should not come in direct contact with

food.

|

Awards

Awards